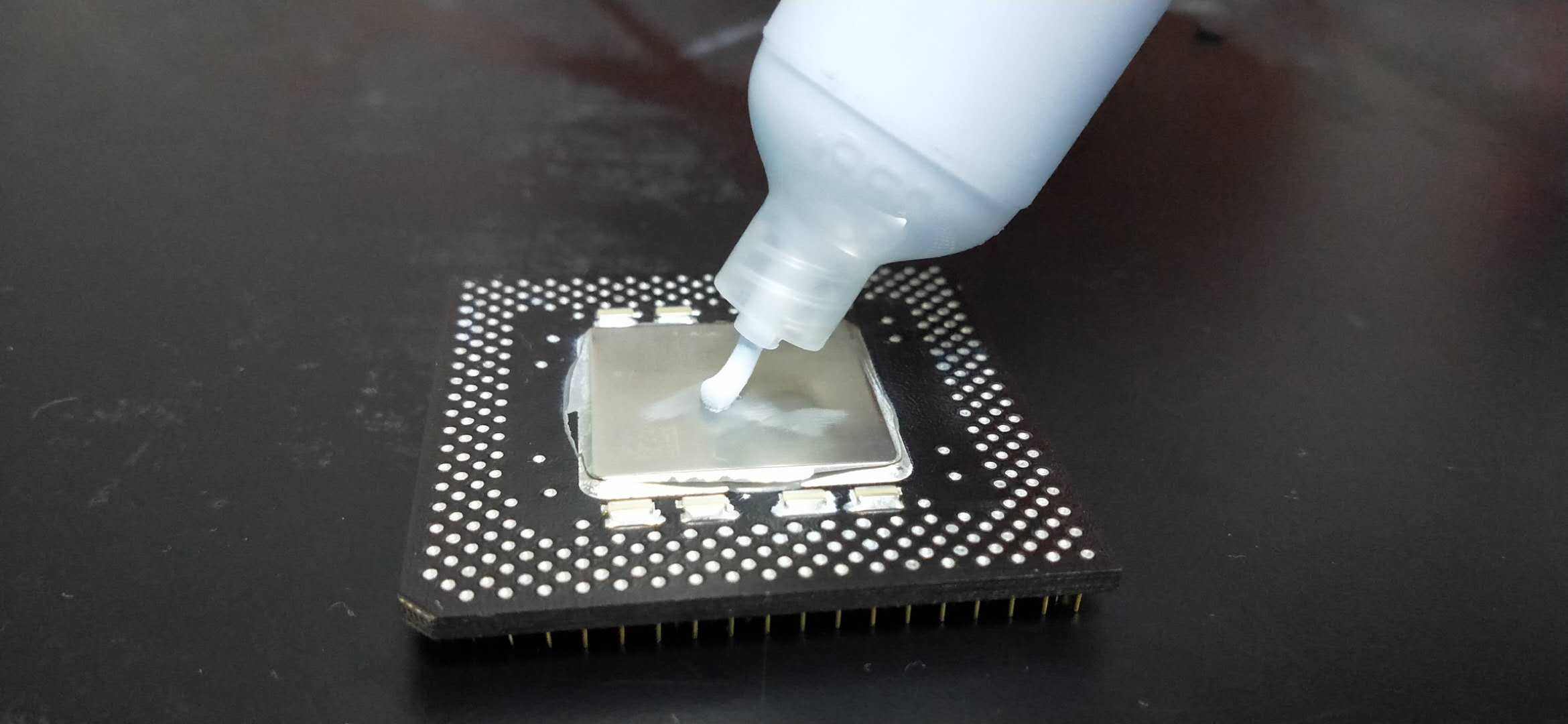

GEL6000 is a high thermal performance, unique, fully cured thermal management solution for electronic assemblies, this material is not dry out. It has low viscosity for dispensing use application; this material have good tacky on the heat-sink can be used for application involving auto-dispensing equipment or stencil screen-printing.

It’s ideal for rework and field repair situations. Compare with thermal pad this material is can fully fill the gap and good compression, cost saving. GEL6000 is RoHS compliant and halogen-free, offering extra reassurance in applications where hazardous substances are forbidden.

Features & Benefit

— Low thermal impedance with thermal conductive 6.0W/mK

— Fill large gaps while providing superior thermally transferability

— Good crumpling resistance, high reliability in long-term work

— Working perfectly on the irregular structure gap

Packing Information

- 30CC syring

- 55CC syring

- 100CC syring

- 300CC cartridge

- 25KG pail

| Property | Data | Test Method |

| Thermal conductive | 6.0W.m-1.K-1 | ASTM D5470 |

| Color | Multi-color | Visual |

| Flow Rate, 30cc syringe with no tip attachment 0.100” orifice, 90psi | 12 g/min | — |

| Density | 3.5g.cm-3 | ASTM D792 |

| Minimum bond line thickness (mm) | 0.1 | — |

| Temperature Range | -55℃~+200℃ | — |

| Breakdown Voltage (V/mm) | >8000 V | ASTM D149 |

| Volume Resistivity | 1013 ohm-cm | ASTM D257 |

| Flammability Rating | V-0 | UL 94 |

| RoHS Compliant | Yes | — |

Reviews

There are no reviews yet.